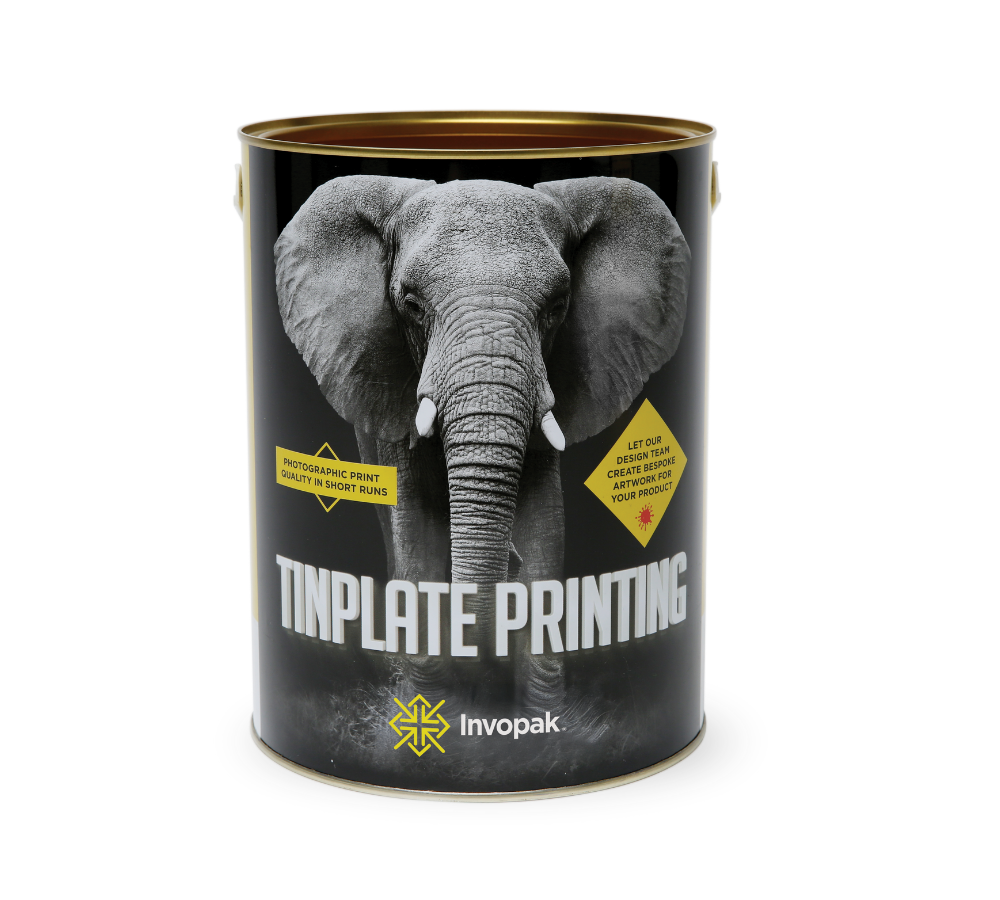

Printed Packaging

Printed packaging is one of the most effective ways to market your brand to your customers and help your products stand out from the crowd.

Offset Printing

Offset lithography transfers ink via a roller directly onto your container, allowing up to 6 colours for sharp, consistent, high quality results. Perfect for bold, vibrant designs.

The offset printing process is a quick process that is best suited to large volumes. Generally speaking, for offset printing, the higher the volume, the lower the price per unit.

The technique used in offset printing means that it can be used to print on a range of surfaces, shapes and sizes. So whether applied to a round plastic bottle, square plastic bucket or round tinplate pail, offset printing will provide a professional finish every time.

In Mould Labelling (IML)

IML embeds a pre-printed polypropylene film directly into the container during

manufacturing, creating a durable, seamless finish that won’t peel or scratch off.

IML ensures a high-resolution finish with outstanding colour quality.

Products with IML are also easier to recycle, as the IML is made of the same material as the container it can be recycled without needing to be separated.

Adhesive Labels

For a branded, professional look without large order commitments, adhesive labels are the ideal solution.

Offering superior print quality, adhesive labels are a great alternative if you cannot meet the minimum order quantities required for IML or Offset printing. This is perfect for trial orders, testing new products or for products supplied in smaller batches.

Please note, we supply printed labels only, this doesn’t include application.

Graphic Design Support

Our in-house design team can craft a striking new design or refine your current artwork.

This services is offered through our sister company Invo Design. Invopak customers get fantastic rates and you can even exchange your Packaging Points for free graphic design time.